diverCity Matchmaking

It’s done! The Private View was a success and the whole journey of rendering and later fabricating the dome was definitely worth it. The lessons have been learnt and looking retrospectively, if I was an architect I’d have never taken upon such a challenge. From the perspective of a graphic designer, the dome seemed relatively easy to make and if not for that naive attitude, the dome might had been just a sketch.

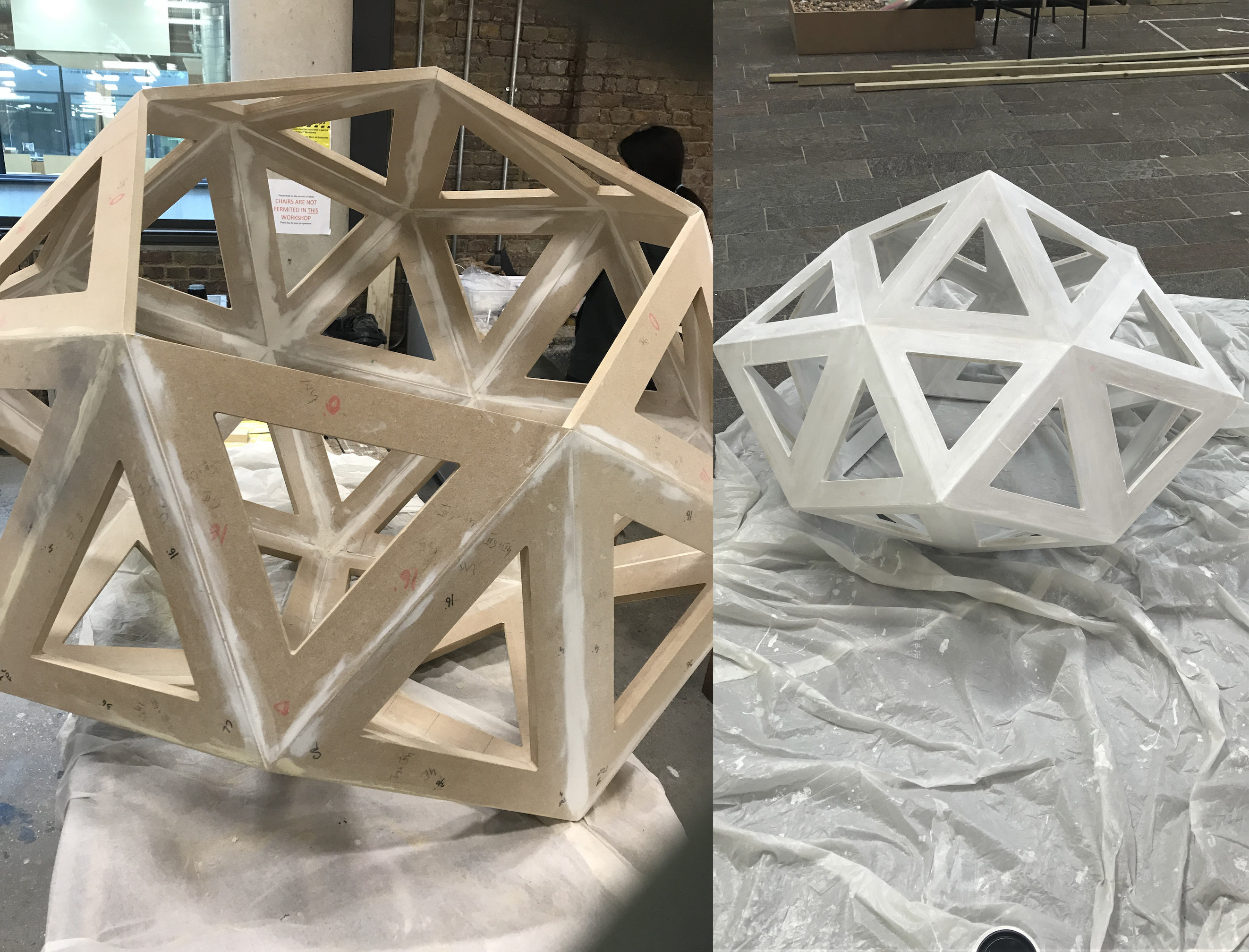

Have a look at the documentation of the glorious process of making the dome.

Process: MDF sheets, CNCed into 35 triangles. Each side of the triangle was then cut at an angle with a table saw and later perforated with a domino machine to accommodate dowels joining the triangles. Once the dome was put together, it was touched up with a wood filler, sanded down, primed and painted with a water-based satinwood ‘Paradise Green 1’.

Once the dome was dry, the four legs and the platform were screwed in.